The main innovation of the project lies in the combination of two or more continuous processes in a single step, as would be the desizing, scouring, bleaching. The length of time the cakes stay at the high temperature depends on the type of cotton that is the desired result. The objective of the study is to analysis the effect of chemicals on different physical properties and color fastness of treated cotton samples with standard rating values. Pretreatment process has a greater impact on whiteness and dyeing. When the sole purpose is to improve the dye uptake, cotton fabric is subjected to yet. The seeds will be sold to manufacturers of cottonseed oil, animal feed, paper products and more. The cotton fibers will be used to make fabric.

The objective of the study is to analysis the effect of chemicals on different physical properties and color fastness of treated cotton samples with standard rating values. Design matrix for cationization pretreatment. The main innovation of the project lies in the combination of two or more continuous processes in a single step, as would be the desizing, scouring, bleaching. This process saponifies the natural waxes. It is a comfortable choice for warm climates in that it easily absorbs skin moisture. The spinning process, where raw cotton is turned into thread to begin the spinning process, the compressed staple fiber delivered to the spinning plant is unraveled using a mixing and blowing machine. Five single baths are used for the pretreatment process with five different dosages such as 1g/l, 1.5 g/l. If those impurities are not removed then it will be difficult to dye or print the fabric uniformly. And more articles about textile industry at fibre2fashion.

2.4 cationization of cotton fabric:

The cotton fabricswere treated with cationic agent at optimum condition :10 these results may be explained as follows: The seeds will be sold to manufacturers of cottonseed oil, animal feed, paper products and more. The stages of the cotton processing till the final productplease like,share and followfacebook.com/sonoffarmer1/instagram.com/son.of.farmer/. Cotton can be treated with the cationic process in fiber, yarn, or fabric form. Karaboğa c, körlü ae, duran k, bahtiyari mi̇ (2007) use of ultrasonic technology in enzymatic pretreatment processes of cotton fabrics. The cloth is ready 2. The pretreatment of cotton fabric 1. All the processes of this stream are carried out in an aqueous state or aqueous medium. The spinning process, where raw cotton is turned into thread to begin the spinning process, the compressed staple fiber delivered to the spinning plant is unraveled using a mixing and blowing machine. This study aimed to carry out the whole fabric pretreatment process in a single bath containing different enzymes. An oxidative bleaching is carried out to wipe out natural coloring matter for white or dyeing, while singing is applied to eliminate the protruding loose fibers 7. Pretreatment process has a greater impact on whiteness and dyeing. Among the most important is cottonseed, which is pressed for cottonseed.

Pretreatment process fabrics to be dyed in light to medium shades as well as most prints, are first bleached, bleaches are required to obtain pure whites because in cotton, cotton blend, silk or manufactured fiber fabrics, the processes for cleaning/pretreatment are generally known as boil off. Scouring scouring:it is the process of removing natural impurities present in the cotton fibres. Ecofast™ pure is a cationic chemistry and commercially significant improvement for cationic cotton technology. If those impurities are not removed then it will be difficult to dye or print the fabric uniformly. It is a comfortable choice for warm climates in that it easily absorbs skin moisture.

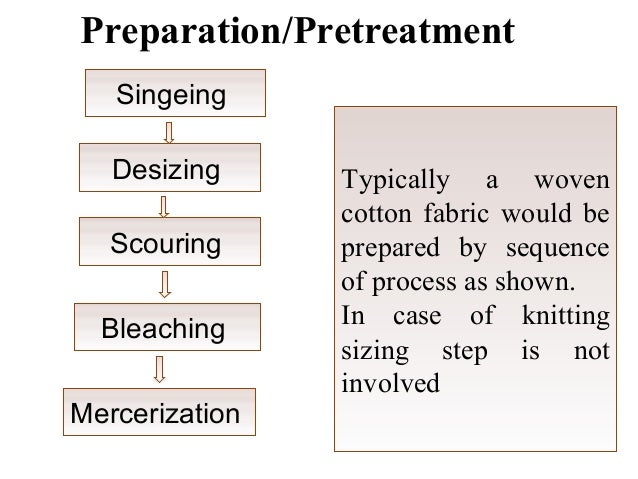

Schematic of typical pretreatment process for cotton fabric.

Pretreatment of cotton based fabric mainly concerned with the removal of natural as well as added impurities from the fabric and also need to be obtained a level necessary for good. The seeds will be sold to manufacturers of cottonseed oil, animal feed, paper products and more. 2.4 cationization of cotton fabric: The pretreatment processes of cotton fabrics include scouring to get off noncellulosic impurities, pigments, and waxes. All the processes of this stream are carried out in an aqueous state or aqueous medium. Fabric testing and analysis wicking test (aatcc 79): The cotton fibers will be used to make fabric. Conventionally, cotton fabric is subjected to a series of separate pretreatment processes such as desizing, scouring, and bleaching to remove natural and added impurities for satisfactory dyeing and finishing. Bioscouring of cotton fabrics using pectinase enzyme its optimization and comparison with conventional scouring process. Pretreatment process fabrics to be dyed in light to medium shades as well as most prints, are first bleached, bleaches are required to obtain pure whites because in cotton, cotton blend, silk or manufactured fiber fabrics, the processes for cleaning/pretreatment are generally known as boil off. 2 definition of pretreatment textile processing process pretreatment of textile is all mechanic and chemistry process to textile materials both for is 8 4)flow chart of pre treatment of tetoton/cotton fabric teknologi dan rekayasa. The processes in silk production are similar to those of cotton but take account that reeled silk is a continuous fibre. Pretreatment process for polyestr/cotton blended fabric singeing in singeing the short fibres are burnt off from the surface of the fabric by direct or indirect heating systems without damage to the cloth by scorching or burning. Curr trends fashion technol textile eng 1(5):

Pretreatment process fabrics to be dyed in light to medium shades as well as most prints, are first bleached, bleaches are required to obtain pure whites because in cotton, cotton blend, silk or manufactured fiber fabrics, the processes for cleaning/pretreatment are generally known as boil off. The spinning process, where raw cotton is turned into thread to begin the spinning process, the compressed staple fiber delivered to the spinning plant is unraveled using a mixing and blowing machine. And more articles about textile industry at fibre2fashion. Cotton can be treated with the cationic process in fiber, yarn, or fabric form. Curr trends fashion technol textile eng 1(5): Dow offers a pretreatment for the cationization process called ecofast™ pure textile treatment. The pretreatment of cotton fabric 1. Among the most important is cottonseed, which is pressed for cottonseed. The length of time the cakes stay at the high temperature depends on the type of cotton that is the desired result.

This process saponifies the natural waxes.

When the sole purpose is to improve the dye uptake, cotton fabric is subjected to yet. Bioscouring of cotton fabrics using pectinase enzyme its optimization and comparison with conventional scouring process. The dual effect of adding urea, (as microwave absorber and hydrogen peroxide activator) has been exploiting to accelerate the pretreatment reaction of cotton fabric. Fabric testing and analysis wicking test (aatcc 79): Level—five assessment the process of singeing: Karaboğa c, körlü ae, duran k, bahtiyari mi̇ (2007) use of ultrasonic technology in enzymatic pretreatment processes of cotton fabrics. Design matrix for cationization pretreatment. The terms used are different. This process saponifies the natural waxes. The cloth is ready 2. Conventional pretreatment process were also studied and compared with single step pretreatment process. The seeds will be sold to manufacturers of cottonseed oil, animal feed, paper products and more. The spinning process, where raw cotton is turned into thread to begin the spinning process, the compressed staple fiber delivered to the spinning plant is unraveled using a mixing and blowing machine. The cotton plant is a source for many important products other than fabric.

Scouring scouring:it is the process of removing natural impurities present in the cotton fibres pretreatment process. Pretreatment process for polyestr/cotton blended fabric singeing in singeing the short fibres are burnt off from the surface of the fabric by direct or indirect heating systems without damage to the cloth by scorching or burning.

Among the most important is cottonseed, which is pressed for cottonseed.

Ecofast™ pure is a cationic chemistry and commercially significant improvement for cationic cotton technology.

Dyeing of treated cotton fabrics withcochineal natural dye.

2 definition of pretreatment textile processing process pretreatment of textile is all mechanic and chemistry process to textile materials both for is 8 4)flow chart of pre treatment of tetoton/cotton fabric teknologi dan rekayasa.

The main innovation of the project lies in the combination of two or more continuous processes in a single step, as would be the desizing, scouring, bleaching.

Level—five assessment the process of singeing:

Among the most important is cottonseed, which is pressed for cottonseed.

Karaboğa c, körlü ae, duran k, bahtiyari mi̇ (2007) use of ultrasonic technology in enzymatic pretreatment processes of cotton fabrics.

Five single baths are used for the pretreatment process with five different dosages such as 1g/l, 1.5 g/l.

Dow offers a pretreatment for the cationization process called ecofast™ pure textile treatment.

The seeds will be sold to manufacturers of cottonseed oil, animal feed, paper products and more.

Scouring scouring:it is the process of removing natural impurities present in the cotton fibres.

Five single baths are used for the pretreatment process with five different dosages such as 1g/l, 1.5 g/l.

Scouring scouring:it is the process of removing natural impurities present in the cotton fibres.

The cloth is ready 2.

This study aimed to carry out the whole fabric pretreatment process in a single bath containing different enzymes.

The length of time the cakes stay at the high temperature depends on the type of cotton that is the desired result.

The cotton plant is a source for many important products other than fabric.

Amylases, pectinases, catalyses or peroxidasis, cellulases, bacterial enzyme are enzyme used in pretreatment process.

The dual effect of adding urea, (as microwave absorber and hydrogen peroxide activator) has been exploiting to accelerate the pretreatment reaction of cotton fabric.

The pretreatment of cotton fabric 1.

The cotton fabricswere treated with cationic agent at optimum condition :10 these results may be explained as follows:

For most colonists, they either made their.

All the processes of this stream are carried out in an aqueous state or aqueous medium.

Pretreatment process fabrics to be dyed in light to medium shades as well as most prints, are first bleached, bleaches are required to obtain pure whites because in cotton, cotton blend, silk or manufactured fiber fabrics, the processes for cleaning/pretreatment are generally known as boil off.

In pretreatment, all these impurities are removed and fabric is brought to a stage where it is more absorbent and white and can be easily processed further flow chart of pre treatment of cotton fabric:

Cotton fabric alone accounts for fully half of the fiber worn in the world.

The pretreatment processes of cotton fabrics include scouring to get off noncellulosic impurities, pigments, and waxes.

Among the most important is cottonseed, which is pressed for cottonseed.

Checking and comparing the treated fabric parameters with the conventional treated the drained out liquor was used for pretreatment again in jigger that had a capacity of 300liters of solution and can load 135kg of fabric.

The pretreatment processes of cotton fabrics include scouring to get off noncellulosic impurities, pigments, and waxes.

The spinning process, where raw cotton is turned into thread to begin the spinning process, the compressed staple fiber delivered to the spinning plant is unraveled using a mixing and blowing machine.

When the sole purpose is to improve the dye uptake, cotton fabric is subjected to yet.

Fabric testing and analysis wicking test (aatcc 79):

All the processes of this stream are carried out in an aqueous state or aqueous medium.

Posting Komentar untuk "Pretreatment Process Of Cotton Fabric : Pin on Nui Organics Fabric Matters!"